The Japanese company Lib Work has presented the technology of building 3D houses, which involves soil as the main ingredient. Business Lib Earth House Construction (Machine translation) The process uses a massive 3D printing team, or rather others, which we saw to build a cafe, bus stops and so on. However, instead of relying on cement to create concrete, the Lib Lib apartment uses a patent mixture of soil, poured lime and natural fibers.

The mixture of materials presented above reminds us a bit Wattle and Daub, building material and technique, which lasts about 6,000 years. Wattle and Daub buildings are known for being useful as long as 700 years. So there should be no worries related to life in a “mud” house, if the construction was completed correctly. In fact, Lib Work notes that its structures “have an equivalent resistance to an earthquake, which makes him a safe house where you can live even in Japan, a country susceptible to earthquakes.” Indeed, class 3 is the highest assessment of such architectural durability in Japan.

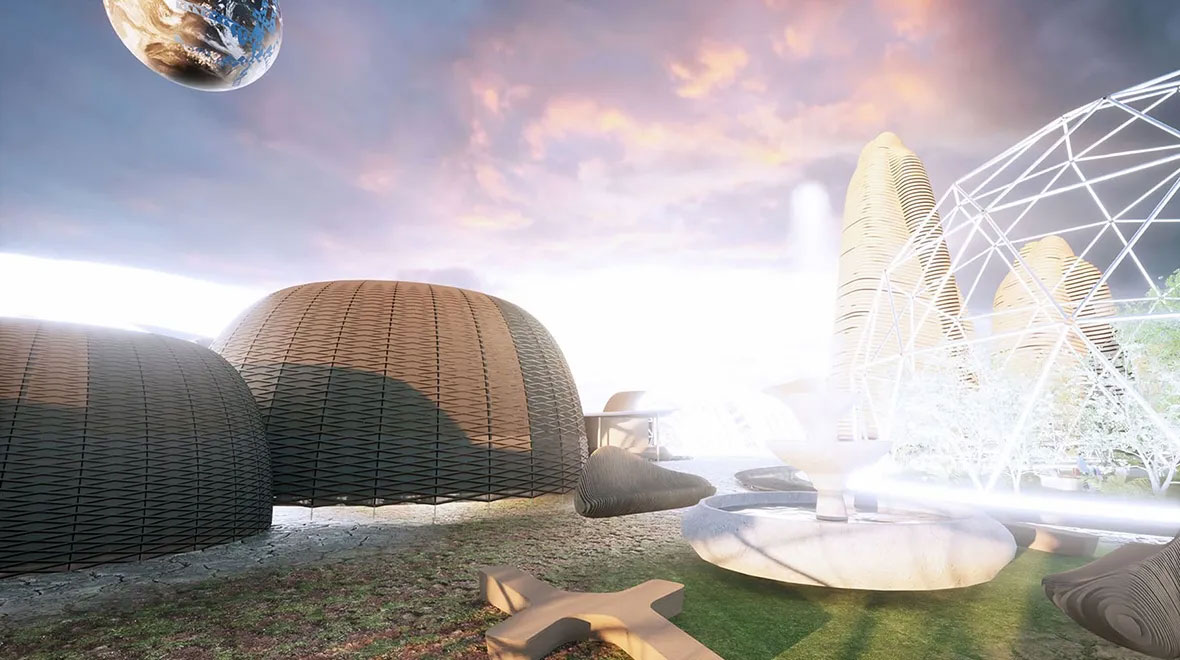

Another attraction of the 3D printed house is that it opens the flexibility of designing a free form. Structures that would be a challenge to make customary materials from a building sheet do not might challenge 3D printers. Lib’s work presented them with the first construction of Lib Earth a year ago, but it was basically only a diminutive cottage. The Lib of Earth B model, recently presented, with its cluster system, is much more sophisticated and home, as you can see in the pictures.

A closer look at the implications of materials and sustainable development

The Lib Work charts indicate that its 3D printing mix for houses is made of 65% soil and sand, with the next largest fragment consisting of a fed the lime binding material, finished with several percent of natural fibers and “other” things.

The company has made some CO2 emissions calculations / measurements. According to these forms, relying on up-to-date material on “soil, lime and natural fibers that are abundantly available on Earth”, and avoiding cement means much lower CO2 generated for residence.

Lib work figurines show that building a typical home of this growth can cause about 45,000 kg of CO2 emissions. This number is reduced by more than half, to 22,434 kg of CO2, using up-to-date construction technology and sustainable 3D printing materials. It’s even better than a “wooden house” they say.

Lib work mars project

If you think that the above Lib Earth project is quite ambitious, moving further to the connected page, you will find information about the arousing of eyebrows about the Mars construction design.

Of course, on Mars, the main element of Lib’s work would be Martian dirt.

Soil balls

Soil and dirt are generally considered low materials, even stretching to insult. However, the status of common land can improve, becoming a valued building material for contemporary, balanced 3D printed apartments.

The soil is actually one of the key ingredients of the glossy balls of Hikaru Dorodando. Numerous YouTube films provide evidence that dirt is possible. Whether this technique can be used in the finish of your 3D -printed soil, in terms of the marble effect features, will just be seen.

Follow Tom’s equipment in Google News To get current messages, analysis and reviews in your channels. Click the Fight button.